What is PEB Structure?

PEB is also referred to as a Pre-engineered Building. Pre Engineered Buildings (PEB) is a modern construction technique where the building components are designed, engineered and fabricated in a factory controlled environment and then transported to the construction site for assembly. PEB systems are unlike traditional construction, whereby raw materials are transported to the site and built out of raw steel sections, which are all meticulously engineered to fit together perfectly. This method has several advantages, such as faster construction time, greater accuracy in the assembly process and less dependence on on site labor. The steel components are custom designed to the building size, layout and use, providing high flexibility.

After being delivered to the site, these components can be rapidly assembled, using bolted connections, and reduce the time and complexity normally required for conventional construction. This approach not only minimizes waste and material handling but also results in a more sustainable and efficient building process. In commercial, industrial and institutional sectors, pre engineered buildings are widely adopted because they are able to meet a variety of functional needs at a cost effective, durable and scalable.

Why PEB is Unique?

Pre-engineered buildings (PEBs) have become the most appropriate solution to the modern construction needs since they are efficient, flexible, and sustainable. Another unique factor that makes PEB stand out is that it is a pre-fabricated building system where the primary steel structure, roof, wall cladding, and other related items are is pre-fabricated to specific requirements. Once designed and manufactured, these components are shipped to the site for quick assembly.

PEBs differ from traditional construction methods in several important ways:

- Factory-Controlled Production: By manufacturing components in a controlled environment, PEBs buildings ensure higher quality and precision, as well as reduced material waste.

- Rapid On-Site Assembly: Once on-site, pre-engineered buildings are assembled quickly using bolted connections, leading to faster project completion compared to traditional construction.

- Lower Costs: The streamlined production and assembly processes allow for significant cost savings by reducing labor costs, minimizing waste, and speeding up the timeline for occupancy.

Learn More About PEB Structures & Sheds

Main Components of PEB (Pre-Engineered Buildings)

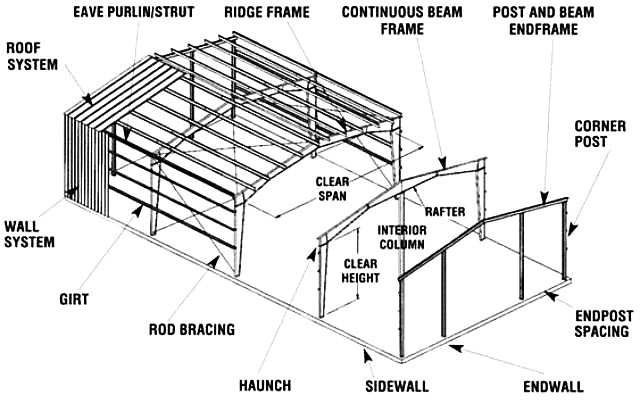

Pre Engineered Buildings are composed of several key elements that come together to form a complete building system. These include:

1. Primary Frames

The primary framing is the steel portions of the building such as columns and rafters that bear the building load. These frames are made with a view to providing strength and durability and are the main load bearing structure of a PEB.

2. Secondary Frames

The second type of framing, also known as purlins and girts, supports the roof and wall panels. These light members enable horizontal forces to be spread across the structure, enhancing stability.

3. Roof and Wall Panels

The roof and wall panels are usually made of corrugated steel sheets or other insulated materials. These panels are available in various finishes and colors and can be tailored to suit the building’s environmental needs, such as thermal insulation or weather resistance.

4. Bracing Systems

The bracing system is designed to resist lateral forces such as wind or seismic activity. These steel braces ensure the building remains stable under external pressures and maintain the structural balance of the frame.

5. Accessories

PEBs can be customized with various accessories, including doors, windows, skylights, and ventilation systems. These accessories are pre-fabricated and designed to fit seamlessly within the structure, enhancing both the functionality and aesthetics of the building.

6. Foundation

Though the components of a PEB are pre-manufactured, the foundation must be prepared on-site. The design of the foundation depends on the building’s size, purpose, and the soil conditions of the construction site.

Advantages of Pre-Engineered Buildings

PEB Buildings offer numerous advantages that make them an ideal choice for a wide range of construction projects. Here are some of the key benefits:

Faster Construction

One of the most significant advantages of PEBs is their speed of construction. Since most of the components are fabricated in a factory, on-site work is minimized. As a result, PEB projects can be completed up to 50% faster than conventional buildings, allowing businesses to become operational more quickly.

Cost-Effective

PEBs provide significant cost savings in terms of labor, materials, and overall construction time. The efficient use of steel, minimal waste, and the reduced requirement for skilled labor on-site all contribute to lower construction costs. Additionally, the faster build times mean that businesses can begin generating revenue sooner.

Flexibility in Design

PEBs are highly customizable, meaning that they can be designed to meet specific requirements for different types of buildings, such as warehouses, factories, office spaces, or even sports arenas. The flexibility in design allows for the inclusion of unique features like mezzanine floors, large spans, and custom exterior finishes.

Durability and Low Maintenance

Steel, the primary material used in PEBs, is highly durable and requires minimal maintenance. It is resistant to environmental factors such as rust, corrosion, termites, and weather damage. PEBs are also designed to withstand harsh weather conditions, including heavy rain, snow, and high winds.

Energy Efficiency

PEBs can be designed with energy-efficient materials and features, such as insulated wall panels and reflective roofing, which help regulate indoor temperatures and reduce heating or cooling costs. Additionally, the use of natural light through skylights can reduce electricity consumption.

Sustainability

Pre-engineered buildings are an eco-friendly option as steel is one of the most recyclable materials. The precision in fabrication also reduces waste during construction, making PEBs a sustainable choice. Many manufacturers offer energy-efficient designs, contributing to long-term sustainability and lower environmental impact.

Scalability and Expansion

PEBs are ideal for businesses that anticipate growth. They can be easily expanded by adding more bays or increasing the height without requiring significant modifications to the existing structure. This scalability ensures that a business can grow its facilities in line with its operational needs.

Reduced Risk of Delays

By reducing the amount of work required on-site and limiting the impact of weather conditions during construction, PEBs minimize the risk of delays that are common in traditional building projects. The factory-controlled production environment ensures that materials are ready for assembly on time.

Applications of PEB

Pre-engineered buildings are suitable for a wide range of applications, owing to their adaptability and durability. Here are some of the most common uses of PEBs:

- Industrial Buildings

- Commercial Buildings

- Institutional Use

- Agricultural Buildings

- Sports Facilities

- Factory

- Warehouse

- Workshop

- Community Hall

- Commercial Showroom

- Cold Storage

- Stadium

- Parking Shed

- Railway Platforms

- Airports

Conclusion

Pre-Engineered Buildings (PEBs) represent a transformative approach to construction, offering speed, cost-efficiency, and customization that traditional building methods often cannot match. Their versatility allows them to be used across various sectors, and the use of steel as the primary material provides strength, durability, and sustainability. PEBs are the ideal solution for businesses looking for a quick, efficient, and long-lasting building option, while also reducing their environmental impact.

By understanding the numerous benefits of PEBs ranging from energy efficiency to scalability businesses can make informed decisions about their construction projects and choose a method that supports both immediate and long-term goals.